With our many years of experience and technical know-how, we know how to transform every project into a functional and aesthetic work. Facades, ceilings, railings, trellises and other metal elements need precise and secure fastening to withstand the test of time and at the same time meet even the most demanding design expectations.

Use our services

Proven fastening systems that combine reliability and aesthetics. Individual solutions tailored to each project. Support and advice from experts who understand the needs of architects.

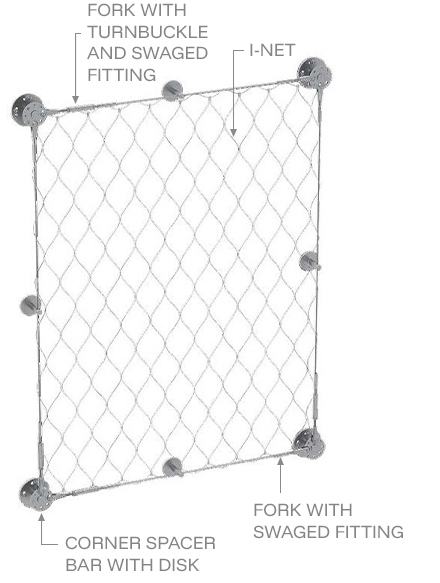

Wire meshes

Frame system for attaching wire mesh

Spiral wire fastening method

Tensile facades

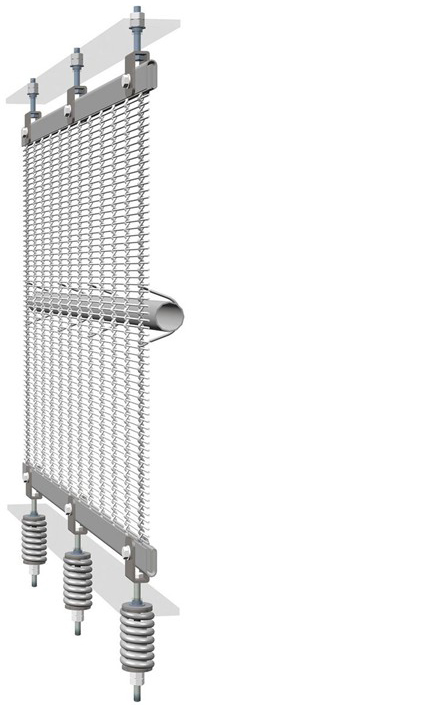

Installation solution for fixed wire mesh facades

| Top mountingThe flat tension profile is equipped with clevis screws, which are used to suspend the element in the substructure. At the same time, tension is applied to the upper fixing point.Intermediate mountingIf the mesh size is large enough, the mesh element is secured using wire connectors. These extend around the tube lying behind the wire mesh from the back into the architectural wire mesh. This middle tube is barely visible when viewed from the front..Bottom mountingFlat tension profiles are used for the bottom fixing, through which tension is applied to the wire mesh using clevis screws. The additional use of compression springs is necessary so that the wire mesh provides the necessary elasticity for the corresponding load in the outdoor area. |

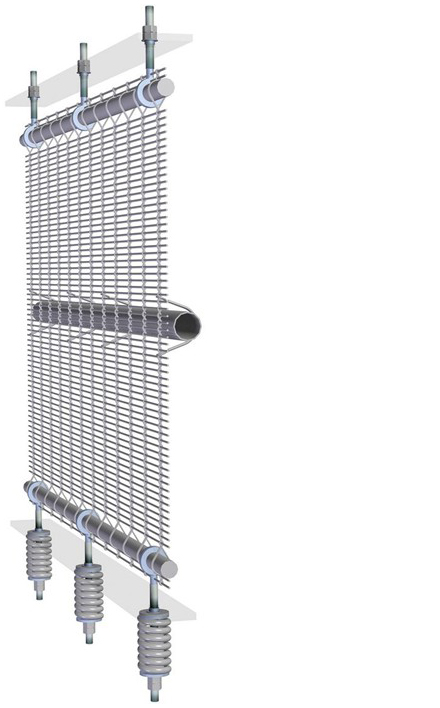

Installation solution for rope net facades

| Top mountingThe cable mesh element is tensioned using eye bolts that are inserted into the cable mesh together with a round bar. The mesh is tensioned either on the continuous profile of the substructure or on individual fastening brackets.Intermediate mountingIntermediate mounting is carried out using cable clamps. These run around the pipe installed behind the cable mesh and hold it in place when connected to the cable groups from the rear. This type of mounting is not visible when viewed from the front.Bottom mountingAnalogously to the top fastening, a round bar is inserted into the cable mesh. The elements are tensioned using eye bolts, for example on a continuous substructure. The eye bolts ensure precise tensioning. Together with compression springs, the mesh is installed with a precise pre-tensioning load. |

Spiral nets

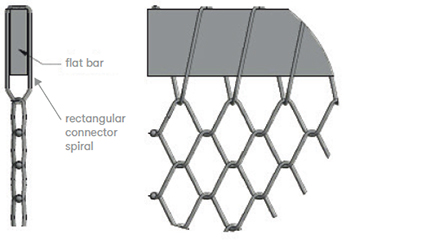

Flat panel with connector spirals

Rectangular connector spiral for flat bar

Flat panel with connector spirals

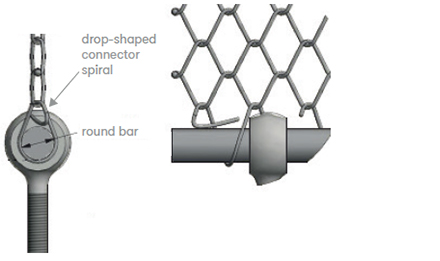

Drop-shaped spiral for round rod

Golf Romeo

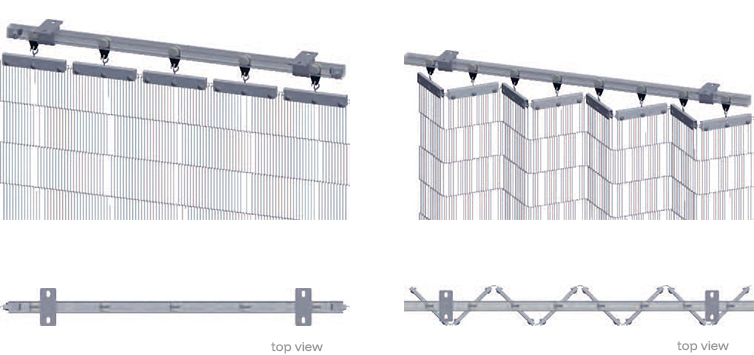

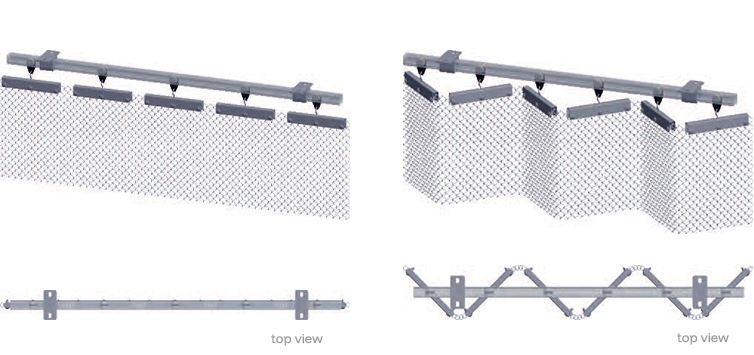

Flat hinge and V-shaped hinge

Sierra Papa

Flat hinge and V-shaped hinge

Golf Romeo

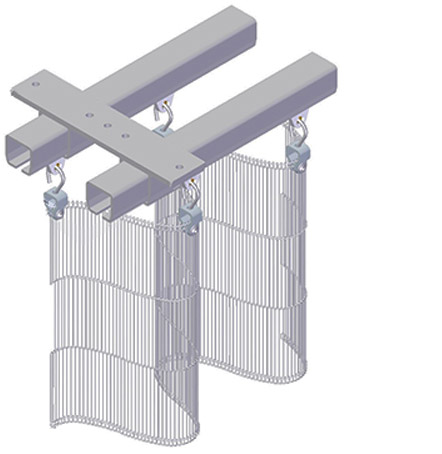

Sinusoidal suspension on two rails

Do you have a challenging project or a specific requirements?

Contact us today and we will find the best solution for your project. Together we will create a space that combines safety, functionality and design.